We used your feedback to design three new Bricklets. All three of them have been released today including lots of accessories:

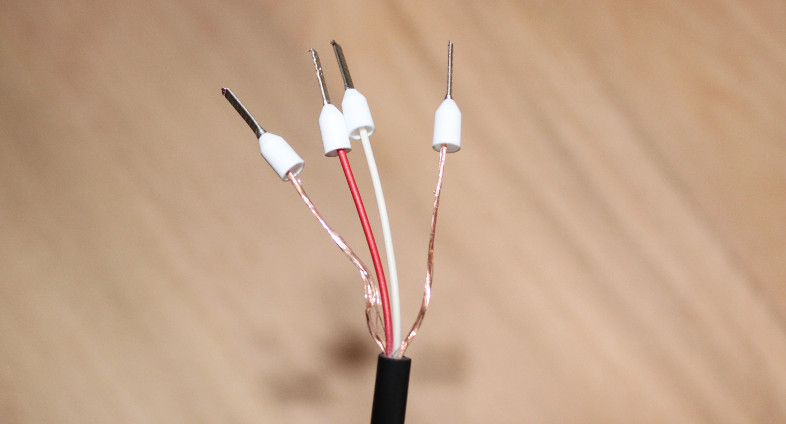

1) Color Bricklet

The Color Bricklet uses a precision color sensor. The sensor can measure RGB color, color temperature and Illuminance with a resolution of 16 bit each! It is possible to enable a defined lightning (by an LED) via software. Using the LED makes it possible to measure the light reflection of an object with high precision and repeatability. A usage for the Bricklet is for example the sorting of objects. While the Ambient Light Bricklet can measure up to ~1000 Lux, the new Color Bricklet can measure values of several 10000 Lux without any problems.

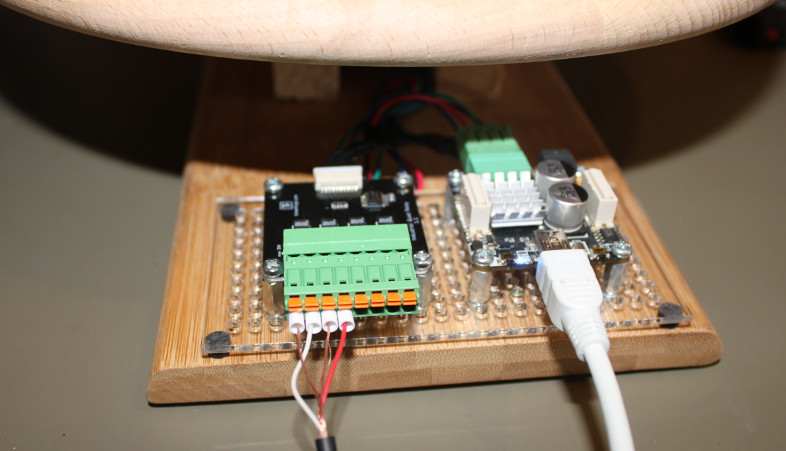

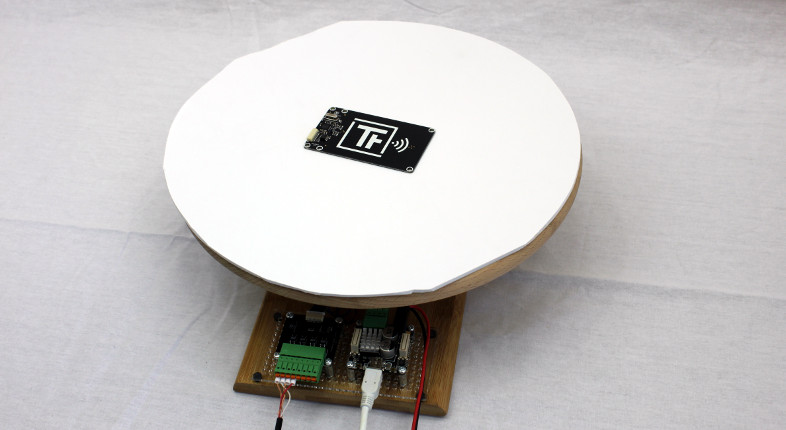

2) NFC/RFID Bricklet

With the NFC/RFID Bricklet you can read and write different 13.56MHz NFC or RFID tags. The Bricklet supports Mifare Classic, NFC Forum Type 1 and 2 RFID/NFC tags with an arbitrary amount of memory. Suitable tags in the form of cards, keyfobs and stickers can be found in our shop. As an example you could build an intelligent cat door with this Bricklet. It could log the enter/leave times, twitter it and similar :-). We have lots of ideas for interesting projects for this product! This example is also good to explain an important feature of NFC: The range is limited to 10cm. The cat door should of course not open itself if the cat is only roughly in the vicinity.

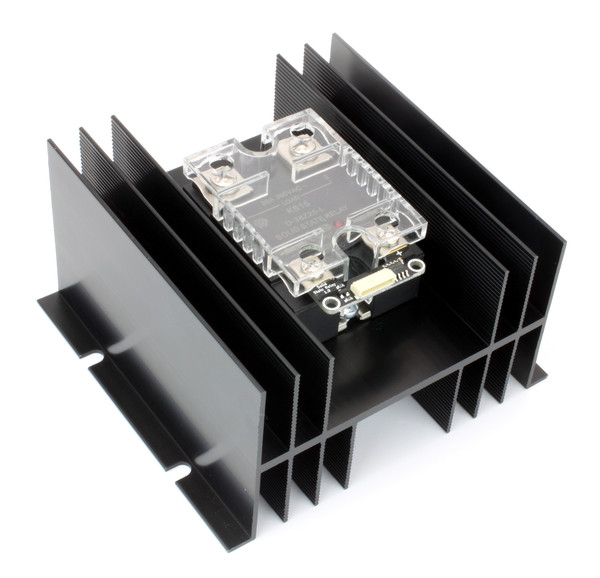

3) Solid State Relay Bricklet

Switching big loads, such as motors, can be problematic. Currently it is possible to use the Dual Relay Bricklet to switch voltages. But especially big 230V loads can be problematic if switched with a mechanical relay. Switching sparks can easily lead to unstable systems. In this case it is possible to use a Snubber (see Dual Relay Bricklet documentation). It is however easier to use a solid state relay. A solid state relay does not switch mechanically, it is a completely electronic switch. Thus there are no switching sparks present whatsoever. A solid state relay also has more switching cycles (it is wear-free) because no mechanical parts are used. It also has a galvanic isolation between the controlling (input) and the load (output).

It is very easy to switch these relays with the Solid State Relay Bricklet. We are offering two different types of relays. One can switch alternating current of up to 25A at 380V and the other can switch direct current of up to 50V at 80A. Additionally we have a cover that can protect you against touching the contacts as well as a heatsink that is necessary if you want to switch big loads.

We tested different types and manufacturers of solid state relays. Please note that the relays in our shop are of high quality compared to some of the super cheap relays that can be bought in china. Although the Bricklet might be compatible to these super cheap relays (at least if you solder a wire to it), we would highly recommend to not use a 2$ relay. We learned our lesson while testing a cheap solid state relay with our electronic load.